The chiller unit (also known as a freezer, refrigeration unit, ice water unit, or cooling equipment) is a type of refrigeration equipment. In the refrigeration industry, chillers are categorized into air-cooled and water-cooled types. Based on the compressor, they are further divided into screw, scroll, and centrifugal chillers. In terms of temperature control, they are categorized into low-temperature industrial chillers and normal-temperature chillers. Normal-temperature chillers are generally controlled within a range of 0°C to 35°C, while low-temperature chillers are generally controlled within a range of 0°C to -100°C.

Chillers are generally categorized by cooling method as water-cooled or air-cooled. Technically, water-cooling offers 300 to 500 kcal/h higher energy efficiency than air-cooling.

Air-Cooled Chillers

Features

1. No cooling tower required, easy installation and relocation, suitable for applications where water is scarce.

2. Low-noise fan motor, excellent cooling and condensing performance, stable throttling mechanism, and excellent rust-proofing.

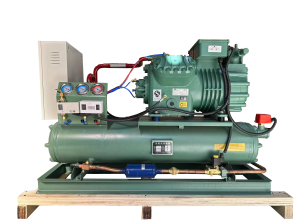

Water-Cooled Chillers

Features

1. Ergonomically designed panel, fully automated control, and precision electric temperature controller ensure long-term stable operation.

2. High-efficiency heat exchangers minimize cooling loss, facilitate oil return, and prevent heat transfer tubes from freezing and cracking.

The water-cooled chiller utilizes a shell and tube evaporator to exchange heat between water and refrigerant. After the refrigerant system absorbs the heat load in the water and cools the water to produce cold water, the compressor brings the heat to the shell and tube condenser. The refrigerant and water exchange heat so that the water absorbs the heat and then takes the heat out of the external cooling tower through the water pipes to dissipate it (water cooling). Initially, the compressor absorbs the low-temperature, low-pressure refrigerant gas after evaporation and cooling, and then compresses it into a high-temperature, high-pressure gas and sends it to the condenser; the high-pressure, high-temperature gas is cooled by the condenser and condensed into a normal-temperature, high-pressure liquid; when the normal-temperature, high-pressure liquid flows into the thermal expansion valve, it is throttled into a low-temperature, low-pressure wet steam and flows into the shell and tube evaporator, absorbing the heat of the chilled water in the evaporator to lower the water temperature; the evaporated refrigerant is then sucked back into the compressor, and the next refrigeration cycle is repeated.

Air-Cooled Screw Chiller

Features

1. The air-cooled condenser is a fin-type, double-oil corrugated hydrophilic aluminum platinum. Manufactured using professional heat exchanger processing equipment, it features a compact structure, small size, light weight, and high heat exchange efficiency. It is equipped with a low-speed, large-blade axial flow fan, effectively reducing operating noise and environmental impact.

2. The unit control system utilizes an imported PLC programmable controller with a large touch screen display for a simple and intuitive interface.

3. The unit is equipped with reliable safety protection devices, including high and low voltage protectors, exhaust overheat protectors, compressor motor overheat protectors, overload current protectors, antifreeze temperature protectors, water flow protectors, emergency stop switches, temperature-sensitive fusible plugs, and safety valves. Water-Cooled Screw Chiller

Features

1. Simple structure, stable heat exchange, long-lasting efficiency, and easy maintenance.

2. The unit’s control system utilizes an imported PLC programmable controller, and the human-machine interface features a large touch screen, offering a simple and intuitive interface and easy operation.

Post time: Aug-09-2025