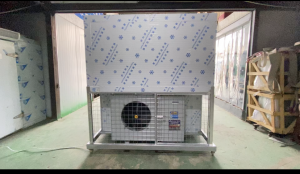

Mobile cold room, also known as portable cold storage, modular cold storage, or prefabricated cold storage, includes fresh-keeping cold storage, frozen cold storage, and dual-temperature cold storage. It can be customized to meet different user needs in terms of size, structure, materials, temperature zones, and other aspects. Due to its convenience and mobility, mobile cold storage is widely used for the freezing and refrigeration of various items such as fresh fruits and vegetables, food, and pharmaceuticals. Mobile cold storage can overcome the influence of climate, extend the storage and preservation period of agricultural and livestock products, and thus regulate market supply.

Mobile Cold Storage Classification

Based on their function, mobile cold storage can generally be divided into three categories: production cold storage, distribution cold storage, and residential service cold storage. Production cold storage is typically built in areas with concentrated sources of goods and mainly serves as part of the cold storage system for cold chain processing and food production enterprises. Its characteristics include large cold processing capacity and the ability to store goods in bulk and release them in batches.

From an equipment structure perspective, there are two types: refrigerated container cold storage and small modular cold storage. While their functional designs are similar, their applications differ. Container cold storage is primarily used for long-distance distribution of cold chain goods by rail and sea. The container dimensions are relatively uniform, and they are mostly powered by generators or external power sources, facilitating intermodal transport. Modular cold storage offers diverse refrigerated volume specifications, is suitable for small trucks, and uses non-fixed refrigerated compartments for easy loading and unloading.

General Design Principles for Mobile Cold Storage

Coverage Dimensions:

The dimensions of a mobile cold storage unit should be determined not only by storage needs but also by transportation conditions. It should not exceed the cargo dimensions of a flatbed truck, especially the height of the unit, which should not exceed the stacking height required by transportation regulations. According to the Ministry of Transport’s “Regulations on the Management of Oversized and Overweight Vehicles on Highways,” a total height of 4 meters or a total width exceeding 2.55 meters from the ground constitutes oversized transport.

Internal Temperature:

Considering actual usage needs and the storage temperature of most goods, -18°C is chosen as the storage temperature for low-temperature cold storage, while 0°C to 5°C can be selected for high-temperature cold storage.

Refrigerant Selection:

Considering the inconvenience of maintenance and repair at the usage location, commonly used refrigerants are generally selected, such as R404A and R407C.

Power Supply:

Depending on the conditions and needs of the usage location, mobile cold storage units can be equipped with either a self-contained power supply or an external power supply. A self-contained power supply means the mobile cold storage unit has its own generator set to provide power. The advantages of self-contained power supply are that it is not limited by external conditions, has strong independence, and can achieve full temperature control within the cold storage during transportation and deployment. Its disadvantages are that generator sets significantly increase the weight of the mobile cold storage and occupy space, reducing the internal volume and storage capacity, resulting in slightly lower economic efficiency.

External power supply refers to power supplied from an external source, with the cold storage’s built-in electrical control system configuring the external power supply. The advantages of externally powered mobile cold storage are lower overall weight, higher internal volume, and better economic efficiency. Its disadvantages are high dependence on the external environment, as the refrigeration units mostly use 380V, limiting its use in some remote locations.

Comparison of Mobile Cold Storage and Conventional Cold Storage

Lifespan Comparison

Conventional prefabricated cold storage units are difficult to disassemble and reassemble. Each disassembly and reassembly significantly impacts the performance and lifespan of the cold storage unit, making them unsuitable for frequent relocation. Mobile cold storage units, on the other hand, are suitable for relocation; each move does not significantly affect the cold storage unit, resulting in a much longer lifespan compared to conventional cold storage units.

Cost Comparison

Mobile cold storage is an extension of conventional prefabricated cold storage. In terms of consumables, material costs are slightly higher compared to conventional prefabricated cold storage units of the same volume. However, in terms of construction and installation costs, mobile cold storage units are designed and manufactured in a factory, allowing for plug-and-play operation on-site without the need for on-site assembly. Therefore, construction and installation costs are significantly lower. Considering the relocation considerations, its cost is far lower than that of prefabricated cold storage units.

Guangxi Cooler Refrigeration Equipment Co.,Ltd.

Email:info01@coolerfreezerunit.com

Tel/WhtasApp:008613367611012

Post time: Dec-31-2025