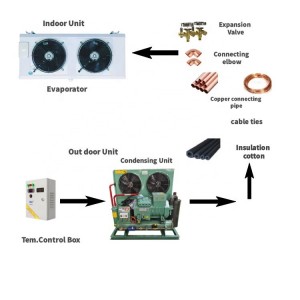

Guangxi Cooler Refrigeration Equipment Co., Ltd. has emerged as a leader in the refrigeration field with its patented “One-to-Two Cold Storage Refrigeration Unit,” bringing a fresh perspective to cold storage unit design. As people’s living standards improve, their demands for food preservation are becoming increasingly stringent. Cold storage facilities must not only meet freezing needs but also accommodate refrigeration. Traditional cold storage facilities often have separate refrigeration units for high-temperature and low-temperature storage, resulting in high equipment costs, large footprints, and considerable energy consumption. Xinshengqi Environmental Protection’s one-to-two cold storage refrigeration unit cleverly solves these problems. It mainly consists of the cold storage unit itself, the refrigeration unit itself, and the electrical control box. High-temperature and low-temperature storage areas are respectively located on the left and right sides of the cold storage unit, laying the foundation for a shared single unit in terms of hardware layout. The refrigeration unit itself includes core components such as the inlet pipe, return pipe, compressor, condenser, fan, liquid receiver, evaporator, and blower. The inlet pipe has a three-way pipe structure, with its outer ends connected to the high-temperature storage area, the low-temperature storage area, and the compressor, achieving efficient refrigerant delivery. The return gas pipe is also a three-way pipe, connecting to the high-temperature and low-temperature storage compartments via a back pressure valve and a one-way valve, respectively, and then to the evaporator, forming a complete refrigerant circulation loop.

The back pressure valve plays a crucial role in this system. In the refrigeration system, the back pressure valve acts like a precise “pressure regulator.” When the high-temperature and low-temperature storage compartments operate simultaneously, the different evaporation temperatures result in different return gas pressures. The back pressure valve automatically adjusts its opening degree according to the system pressure through its built-in spring force. When the return gas pressure in the high-temperature storage compartment falls below the set value, the spring force closes the valve core, preventing gas backflow and ensuring that the evaporator in the high-temperature storage compartment maintains the required evaporation pressure, thereby stabilizing the storage temperature. For example, in fruit and vegetable cold storage, the high-temperature compartment stores tropical fruits such as bananas, requiring a temperature of 12-14℃. The back pressure valve can precisely regulate this, allowing the evaporator to operate at the appropriate evaporation pressure, ensuring the bananas remain fresh. Furthermore, when the high-temperature storage unit operates alone, the back pressure valve and check valve work together to prevent the return gas from the high-temperature storage unit from flowing back and condensing into the low-temperature storage unit, thus preventing excessive liquid return during startup, ensuring stable oil return, and guaranteeing safe and efficient system operation.

Simultaneously, both the high-temperature and low-temperature storage units utilize four-sided smooth aluminum tubing. This tubing not only boasts excellent thermal conductivity and strong cold storage capacity, but also features oil return bends at its ends, enabling effective and rapid oil return and ensuring stable operation of the refrigeration system. This dual-unit design allows one unit to meet two different temperature requirements, significantly reducing equipment procurement costs and energy consumption. In practical applications, it saves many cold chain companies approximately 30% on equipment investment and 20% on energy consumption, ushering in a new era of energy conservation in cold storage.

Guangxi Cooler Refrigeration Equipment Co.,Ltd.

Email:info01@coolerfreezerunit.com

Tel/WhatsApp:+8613367611012

Post time: Dec-11-2025