The composition of the cold storage is divided into five parts: cold storage unit, cold storage board (including cold storage door), evaporator, distribution box, copper pipe.

Cold storage

1. Let’s talk about the cold storage board first:

The cold storage board is composed of outer layer material and inner layer material. The thickness of the cold storage board is divided into five types: 75mm, 100 mm, 120 mm, 150 mm, and 200mm.

The outer layer material is divided into three types: color steel plate, embossed aluminum plate, Baosteel plate, and stainless steel plate. The thickness of the outer layer material is divided into 0.4mm, 0.5mm, etc. The inner layer material is made of polyurethane foam.

The commonly used cold storage board is 100 mm, which is composed of 0.4mm thick color steel plate plus polyurethane foam. The thicker the cold storage board, the better the insulation effect. The cold storage board can be customized according to customer needs.

There are three types of cold storage doors: sliding doors, sliding doors, and double doors. The size and thickness of the door, the board, etc. can be customized according to customer requirements.

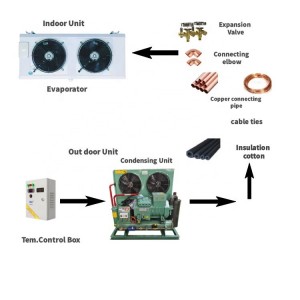

2. Cold room condensing unit:

The working process of the cold room refrigeration system is formed by compressor—> condenser—> liquid storage tank—> filter—> expansion valve—> evaporator.

There are many brands of compressors: Copeland (USA), Bitzer (Germany), Sanyo (Japan), Tecumseh (France), Hitachi (Japan), Daikin (Japan), Panasonic (Japan).

Similarly, the brands of refrigerants added to each compressor are different, including R12, R22, R134a, R404a, R410a, R600

Among them, R134a, R404a, R410a, and R600 are environmentally friendly refrigerants. , The pressure values added to different refrigerants are also different.

1. The function of the condenser is to dissipate heat for the compressor.

If the condenser is very dirty, or the cold storage unit is installed in a place with poor heat dissipation, it will directly affect the refrigeration effect of the cold storage. Therefore, under normal circumstances, the condenser needs to be cleaned once every three months, and the cold storage unit must be installed in a well-ventilated place that is conducive to heat dissipation.

2. The function of the liquid storage tank is to store liquid refrigerant

When the refrigeration system is running, the compressor will compress the gas to the condenser to dissipate heat, and liquid refrigerant and gaseous refrigerant will flow together in the copper tube. At this time, when there is too much liquid refrigerant, the excess will be stored in the liquid storage tank. If the liquid refrigerant required for refrigeration is less, the liquid storage tank will automatically replenish it.

3. The function of the filter is to filter impurities

The filter will filter out the debris or impurities generated by the compressor and copper tube during refrigeration, such as dust, moisture, etc. If there is no filter, these debris will block the capillary or expansion valve, making the system unable to refrigerate. When the situation is serious, the low pressure will be negative pressure, which will cause damage to the compressor.

4. Expansion valve

Thermostatic expansion valve is often installed at the entrance of the evaporator, so it is called expansion valve. It has two main functions:

①. Conversion. After the high-temperature and high-pressure liquid refrigerant passes through the conversion hole of the expansion valve, it becomes a low-temperature and low-pressure mist-like hydraulic refrigerant, creating conditions for the evaporation of the refrigerant.

②. Control the flow of the refrigerant. The liquid refrigerant entering the evaporator evaporates from liquid to gas after passing through the evaporator, absorbs heat, and reduces the temperature in the cold storage. The expansion valve controls the flow of the refrigerant. If the flow is too large, the outlet contains liquid refrigerant, which may enter the compressor to cause liquid accumulation. If the flow is small, the evaporation is completed in advance, which will cause insufficient refrigeration of the compressor.

3. Evaporator

The evaporator is a wall-type heat exchange device. The low-temperature and low-pressure liquid refrigerant vaporizes and absorbs heat on one side of the heat transfer wall of the evaporator, thereby cooling the medium on the other side of the heat transfer wall. The cooled medium is usually water or air.

Therefore, evaporators can be divided into two categories. Evaporators that cool liquids and evaporators that cool air. Most cold storage evaporators use the latter.

4. Electric box

The distribution box needs to pay attention to the installation location. Generally, the distribution box will be installed next to the cold storage door, so the cold storage power line is usually equipped 1-2 meters next to the cold storage door.

5. Copper pipe

It should be noted here that the length of the copper pipe from the cold storage unit to the evaporator should be controlled within 15 meters. If the copper pipe is too long, it will affect the refrigeration effect.

Guangxi Cooler Refrigeration Equipment Co.,Ltd.

Tel/WhatsApp:+8613367611012

Email:karen@coolerfreezerunit.com

Post time: May-14-2025