Air conditioning and cold storage pressure maintaining operation and precautions.

The refrigeration system is a sealed system. The air-tightness of the refrigeration system after maintenance must be strictly checked to ensure the maintenance quality, improve the reliability of operation, reduce the loss of refrigerant, and improve the economy of operation. The refrigerant is extremely permeable. Therefore, it is necessary to check the air tightness of the refrigeration system.

It should be noted that nitrogen gas must be used to maintain pressure in the refrigeration system. Oxygen is a flammable gas. If oxygen is used to maintain pressure, it may cause fire or explosion!

- Pressure maintaining operation of small and medium cold storage:

It is recommended to pressurize both sides of the gas and liquid at the same time. First, connect the pressure gauge to the multi-purpose channel of the compressor's high and low pressure shut-off valve, and remove the components in the original system that should not be subjected to excessive pressure, such as the evaporation pressure regulating valve and other components.

Taking R22 refrigerant as an example, when the low pressure pressure is 1.2MPa, the nitrogen charging is stopped. After the low pressure section test is completed, the pressure test of the high pressure system is carried out. After the high pressure system pressure is increased to 2.5MPa, nitrogen charging is stopped. Keep the pressure for 24~48h.

| Refrigeration system | R134a | R22 | R401A, R402A,R404A,R407A,R407B,R407C,R507 |

| Low press system | 1.2 | 1.2 | 1.2 |

| High temperature system | 2.0 | 2.5 | 3.0 |

Precautions:

In the first 4 hours of the system, the gauge pressure of the pressure drop does not exceed 0.03MPa, and then continues to be stable (during the test process, the pressure drop due to temperature changes generally does not exceed the gauge pressure of 0.01~0.03MPa), and the refrigeration system can be considered to be qualified for leak testing.

2. Multi-line system pressure maintaining operation

The multi-connector must be pressurized from both sides of the gas pipe and the liquid pipe at the same time, because the pressure on both sides of the gas and liquid can protect the valve parts such as the electronic expansion valve on the indoor unit side of the multi-connector system from being damaged. Dry nitrogen must be used for the air tightness test. make a medium.

During the air tightness test, it is not allowed to connect the pipeline test of the external machine. The test pressure of R410A system is 4.0MPa, the air tightness test must use nitrogen as the medium, and the nitrogen must be dry. Pressurize slowly, in three steps:

| Press | Time | Function |

| 0.3MPa | >5 mins | Large leaks can be found |

| 1.5MPa | >5 mins | Large leaks can be found |

| 4.0MPa | 24h | Small leaks can be found |

1. Pressurize to 0.3MPa, stay for 5 minutes for leakage inspection, and may find large leakage;

2. Pressurize to 1.5MPa, stay for 5 minutes for air tightness inspection, and find small leakage;

3. Pressurize to 4.0MPa, stay for 5 minutes for strength test, and fine blisters may be found.

After pressurizing to the test pressure, keep the pressure for 24 hours, and observe whether the pressure drops. If the pressure does not drop, it is qualified.

Precautions:

Pressure correction: When the temperature changes by 1°C, the pressure changes correspondingly by 0.01MPa. If the pressure needs to be maintained for a long time, the pressure should be reduced to 0.5MPa or below. Long-term high pressure may lead to leakage of welding parts, and there are potential safety hazards;

The pressure after pressure holding is affected by the ambient temperature. As the temperature rises, the pressure will also rise, and as the temperature falls, the temperature will also drop. If the ambient temperature was 10°C when the pressure was maintained yesterday, and the temperature suddenly rose to 25°C today, then If the temperature is 15°C, the pressure gauge will drop, and it is normal for the gauge pressure to be 38.4kgf/cm².

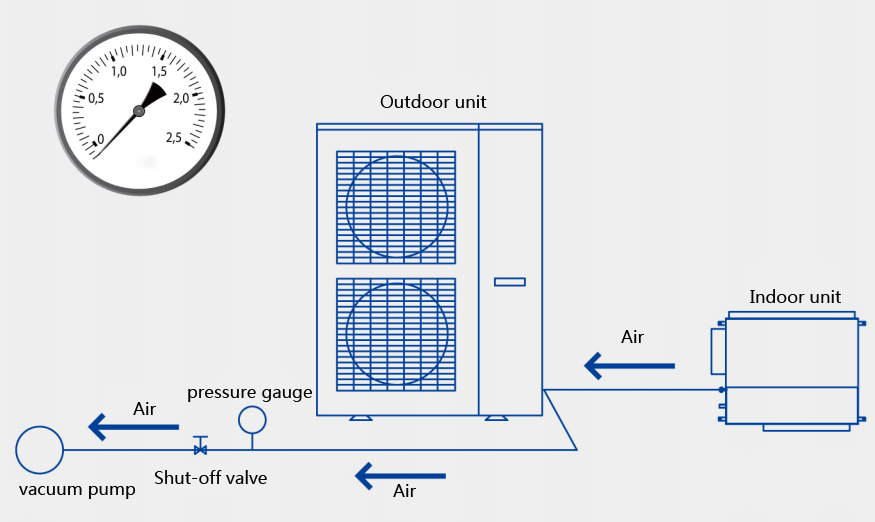

After the nitrogen pressure test is qualified, vacuum dry the system. Connect the vacuum gauge and run the vacuum pump for more than 2 hours. If it cannot reach -755mmHg, continue to pump for 1 hour. After reaching -755mmHg, it can be placed for 1 hour, and it is qualified if the vacuum gauge does not rise.

Post time: Jun-10-2022