1. Make accurate and clear signs in accordance with the drawn construction drawings; weld or install supporting beams, columns, supporting steel frames, etc., and the welds shall be moisture-proof and anti-corrosive in accordance with the requirements of the drawings.

2. The equipment that needs to be installed in the warehouse and needs to enter the warehouse in advance is installed in place or placed in an appropriate position in the warehouse;

3. Install the temporary lighting facilities in the warehouse, install and arrange the electrical equipment for construction, and do a good job of protection against rain, moisture, collisions, and ties.

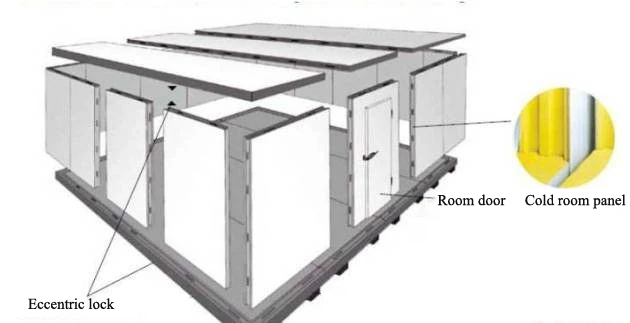

4. Install the wall cold storage board from the corner of the warehouse body, and temporarily fix the corner with 30×30×0.5 color plate angle steel; when installing each wallboard, spread two layers of foaming material evenly on the joint surface of the male and female grooves, and install the poly A strip of foaming material is used when styrene wallboard. Feeding should be uniform and continuous; after the wall panels are installed in place, rivets are used at the overlap of the inner and outer steel plates of the two wall panels to be connected and fixed, and the rivet spacing should be 300mm in the warehouse; the cold storage panels of the eccentric hook connection form should be eccentric before installation The hook is loosened again to ensure reliable locking during installation.

5. The installation of the top cold storage board should be carried out alternately with the installation of the wall board, and the wall board should be left out of the gap for the withdrawal of the construction equipment; when the top storage board is installed, the steel skin at the end of the overlap with the wall board should be disconnected by 50mm to prevent the “cold bridge” from running. Cold; Two layers of foaming material are evenly hit on the joint surface between each top storehouse board. The hitting should be uniform and continuous. The lap joints between the inner and outer parts of the steel plate should be fixed by rivets. The distance between the rivets should be 300mm;

6. In order to ensure the safety of construction and cold storage operation and use, the span between the roof slab supports (lifting points) should meet the following requirements:

Polystyrene roof board (thickness 100mm) with a maximum span of 3 meters;

The maximum span of polyurethane roof board (thickness 100mm) is 5 meters.

7. When installing large-span top cold storage plates, if supporting steel beams have been installed in the storage, the top storage plates and supporting steel beams should be fixed with rivets when installing each storage plate. Each top storage plate should be hit with two rows of three. Rivets; if the type of lifting point is adopted, the installation and construction work of the hanging structure should be completed before the installation of the roof slab to ensure that the lifting points can be installed at the same time during the installation of the roof slab; the lifting point should ensure that each slab is installed There are at least two points along the width.

8. The butt joints of the top cold storage board and the top cold storage board should be treated to prevent air leakage and cold running. After the top library board is fully installed, the butt joints should be filled with foam material, and the 80mm wide color steel plate is covered at the butt joints by pulling riveting.

9. When installing the polystyrene library body, the verticality error of the wallboard should be corrected while the top library board is installed. The length of the top storehouse board should be 10mm shorter than the outer surface of the wallboard. After the top storehouse board is installed, when installing the outer corner, the 10mm gap should be marked with foam to ensure the sealing performance of the storehouse body.

10. When the roof board or wall board needs to be drilled, the internal and external line positioning should be carried out according to the design requirements of the drawing, and the holes should be opened after the check is correct; the line inlet hole, the liquid hole, the air return hole, the water hole, and the drainage hole Use a hole saw to make holes. Carry out the construction treatment in time after opening the hole. Use foam material or sealant to seal the hole to prevent air leakage and run cold; doorways, vents, and cargo openings are decorated with edging and fixed with rivets. The distance between the rivets is 300mm inside and 150mm outside. .

11. The distance between the inner and outer corner pull rivets is 300mm and 200mm respectively; after the polystyrene library body is installed, the joints of the wallboards are evenly sealed and decorated with a silicone sealant.

12. During the cold storage test machine process, someone should check that the outer surface of the storage board should be uniformly reflective, free of condensation and cold running; check the sealing conditions of the joints, openings and perforations; whether the storage doors, cargo ports, etc. are sealed In the case of lax conditions, timely deal with the problems of degumming, air leakage and other heat preservation and sealing failures.

Post time: Nov-29-2021