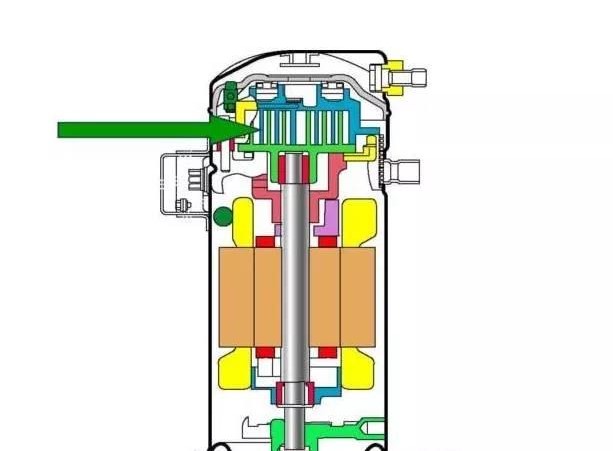

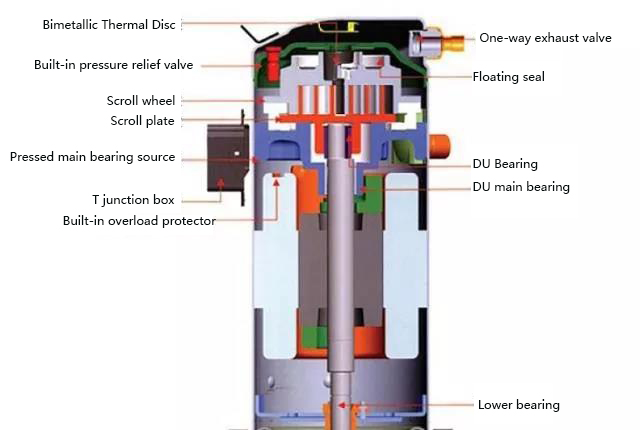

Scroll Compressor Units

Principle: The scroll line shape of the moving plate and the static plate are the same, but the phase difference is 180∘ to mesh to form a series of closed spaces; the static plate does not move, and the moving plate revolves around the center of the fixed plate with the eccentricity as the radius. When the moving disk revolves, it meshes in sequence, so that the crescent-shaped area is continuously compressed and reduced, so that the gas is continuously compressed and finally discharged from the center hole of the static disk.

Structure: moving disc (vortex rotor), static disc (vortex stator), bracket, cross coupling ring, back pressure cavity, eccentric shaft

Advantage:

1. The eccentric shaft driving the moving scroll can rotate at a high speed, and the scroll compressor is small in size and light in weight;

2. The force changes of moving parts such as the movable scroll and the main shaft are small, and the vibration of the whole machine is small;

3. It is suitable for variable speed movement and frequency conversion speed regulation technology;

4. The whole scroll compressor has very low noise;

5. The scroll compressor has reliable and effective sealing, and its refrigeration coefficient does not decrease with the increase of operating time, but slightly increases

6. The scroll compressor has good working characteristics. In the heat pump air conditioning system, it is especially manifested in high heating performance, good stability, and high safety;

7. The scroll compressor has no clearance volume and can maintain high volumetric efficiency operation;

8. The torque change is small, the balance is high, the vibration is small, and the operation is stable, so that the operation is simple and easy to realize the automation;

9. Few moving parts, no reciprocating mechanism, simple structure, small size, light weight, few parts, high reliability, and a life span of more than 20 years.

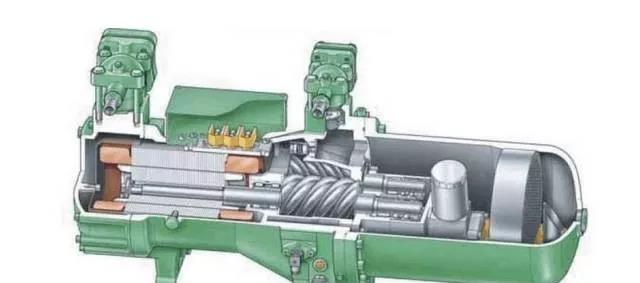

Screw Compressor Units

Principle: Through the mutual immersion of the Yin and Yang rotors and the continuous movement of the space contact line from the suction end to the exhaust end, the volume of the primitive is changed periodically, thereby completing the continuous suction and exhaust process.

Structure: Composed of casing, screw (or rotor), bearing, energy adjustment device, etc.

Advantage:

1. Few parts, less wearing parts and high reliability;

2. Convenient operation and maintenance;

3. There is no unbalanced inertial force. Smooth and safe operation, low vibration;

4. It has the characteristics of forced air delivery, the exhaust volume is almost not affected by the exhaust pressure, and the working conditions are adaptable;

5. The rotor tooth surface of the screw compressor actually has a gap. Therefore, it is not sensitive to wet stroke and can withstand liquid shock;

6. The exhaust temperature is low, and it can be operated under a higher pressure ratio;

7. It can realize stepless adjustment of the refrigeration condition, adopting a sliding valve mechanism, so that the refrigeration capacity can be steplessly adjusted from 15% to 100%, saving operating costs;

8. It is easy to realize automation and can realize remote communication.

Piston Compressor Units

Principle: Relying on the reciprocating motion of the piston to compress the gas in the cylinder. Usually the rotation of the prime mover is converted into the reciprocating movement of the piston through a crank connecting rod mechanism. The work done by the crankshaft for each revolution can be divided into the intake process and the compression exhaust process.

Structure: Including body, crankshaft, connecting rod assembly, piston assembly, air valve and cylinder liner assembly, etc.

Advantage:

1. In the general pressure range, the requirements for materials are low, and ordinary steel materials are mostly used, which is easier to process and lower in cost;

2. The thermal efficiency is relatively high. Generally, the adiabatic efficiency of large and medium-sized units can reach about 0.7~0.85;

3. The severity and characteristics of the gas have little effect on the performance of the compressor, and the same compressor can be used for different gases;

4. The piston compressor is relatively mature in technology, and has accumulated rich experience in production and use;

5. When the air volume is adjusted, the adaptability is strong, that is, the exhaust range is wide, and it is not affected by the pressure level, and can adapt to a wider pressure range and cooling capacity requirements.

Post time: Dec-27-2021