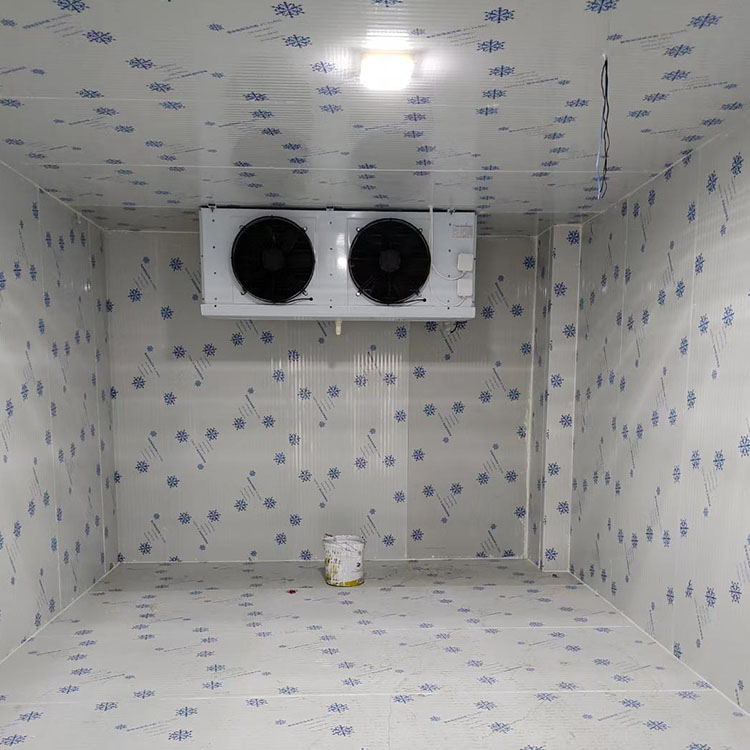

DD40 40㎡ cold storage medium temperature evaporator

Company Profile

Product Description

|

DD40 40㎡ cold storage evaporator |

||||||||||||

|

Ref.Capacity (kw) |

8 |

|||||||||||

|

Cooling Area (m²) |

40 |

|||||||||||

|

Qty |

2 |

|||||||||||

|

Diameter (mm) |

Φ400 |

|||||||||||

|

Air Volume (m3/h) |

2x3500 |

|||||||||||

|

Pressure (Pa) |

118 |

|||||||||||

|

Power (W) |

2x190 |

|||||||||||

|

Oil (kw) |

2.83 |

|||||||||||

|

Catchment Tray (kw) |

0.8 |

|||||||||||

|

Voltage (V) |

220/380 |

|||||||||||

|

Installation Size (mm) |

1520*600*560 |

|||||||||||

|

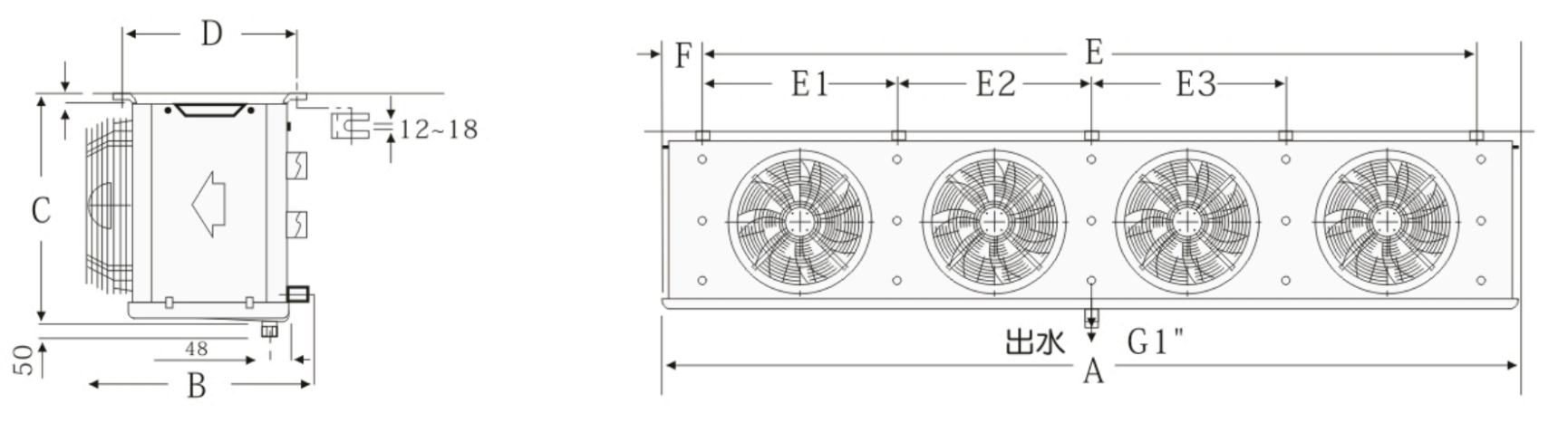

Installation size data |

||||||||||||

|

A(mm) |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

E1(mm) |

E2(mm) |

E3(mm) |

F(mm) |

Inlet tube (φmm) |

Back trachea (φmm) |

Drain pipe |

|

|

1560 |

530 |

580 |

380 |

1280 |

|

|

|

|

16 |

25 |

||

Introduction

Whether the air evaporator is properly installed will directly affect the performance of the entire system and the cooling and heat preservation performance of the cold storage. Therefore, the following instructions should be carefully referred to when installing:

1.During installation, ensure unobstructed air flow, uniform air supply in the cold storage, and convenient maintenance. The fan range of the air cooler is 7 meters. When installing, pay attention to the uniform temperature of cold storage longer than 7 meters.

2.The exhaust direction of the fan should be towards the door as much as possible, and the suction side should avoid the door.

3.The configuration of the liquid supply pipe should ensure sufficient liquid supply and no flash gas before the expansion valve; the configuration of the gas return pipe should ensure that the oil return is smooth and the pressure loss does not exceed 2PSIG. After the air return pipe exits the evaporator, an oil return bend should be added when ascending, and the diameter of the ascending section should be reduced.